Thermoplastic water soluble pellets

The PVAL thermoplastic pellets can be converted by the standard thermoplastic material processes, like extrusion blow molding, injection molding, extrusion vacuum molding etc. into products like bottles, jars, dosing cups and in general into a variety of forms and shapes.

The PVAL thermoplastic pellets can be also converted by blow extrusion into water soluble and biodegradable films. Moreover they can be used in co-

The PVAL has similar barrier properties to EVOH material, but in addition to that it is biodegradable and according to requirements water soluble. It can be easily associated with other polymers by co-

Advantages of thermoplastic pellets :

Water soluble product.

Biodegradable and leaving no toxic residue.

3D

Creation of various 3D shapes.

Applications

Make multiform biodegradable and water-soluble products :

Blow extrusion

(flasks, bottles, dispensers)

3D Printing

Injected parts

(tee and golf ball)

Extrusion coating

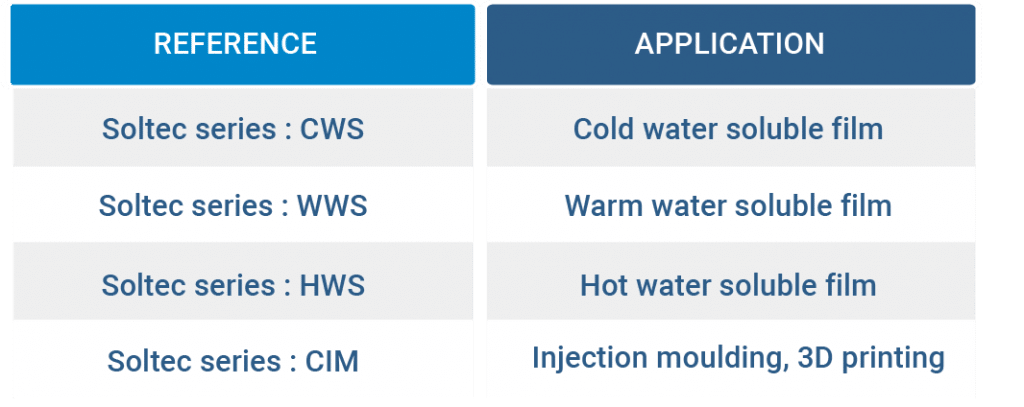

Discover our thermoplastic pellet references :